周日六种方式:诊断ZF6&FORD 6R60 / 80 TC相关的驾驶能力问题

Bob Warnke

What is WK?

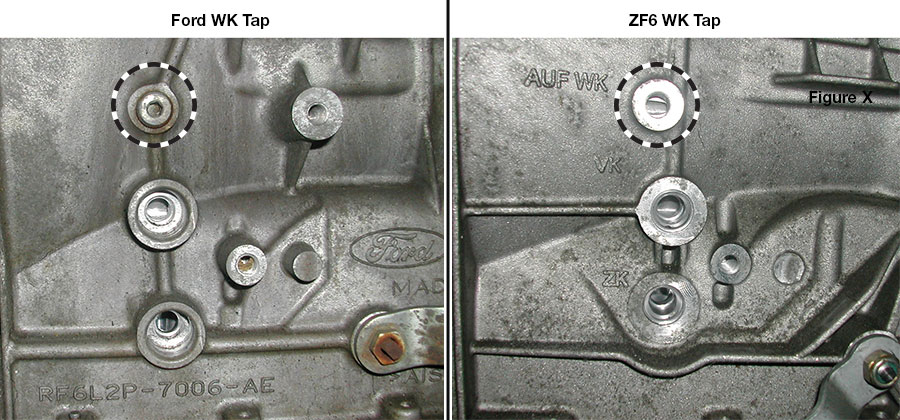

| 图1 |

|---|

|

Accessing WK

Normal WK

| 图2 |

|---|

|

Abnormal WK

- TC Slip

- Partial Release

- TCC/Solenoid/Ratio Codes

- Harsh Shifts

- 耀斑班次

- 反向粗糙闲置

The Root Cause

A Ford Note

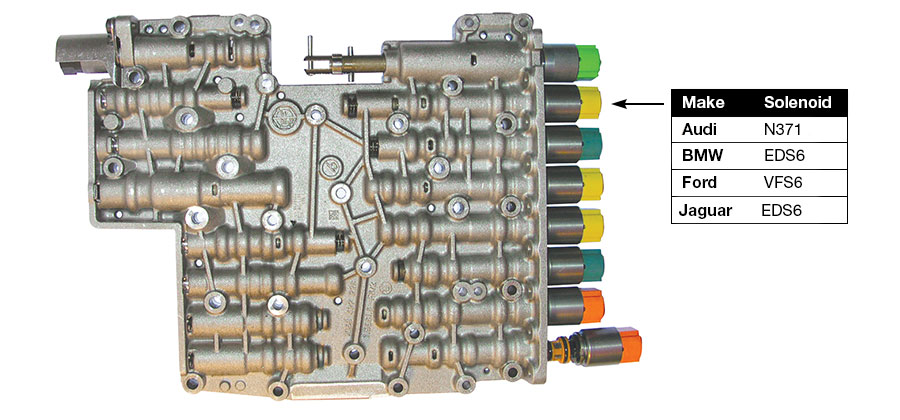

No Mechatronic Swapping Allowed

把它带回家

Related Units

Related Parts

Required

Recommended

6R100.那6R60.那6R75那6R80 (2009-2014)那6R80(2015年后)那ZF6HP19那ZF6HP21那ZF6HP26那ZF6HP28那ZF6HP32那ZF6HP34

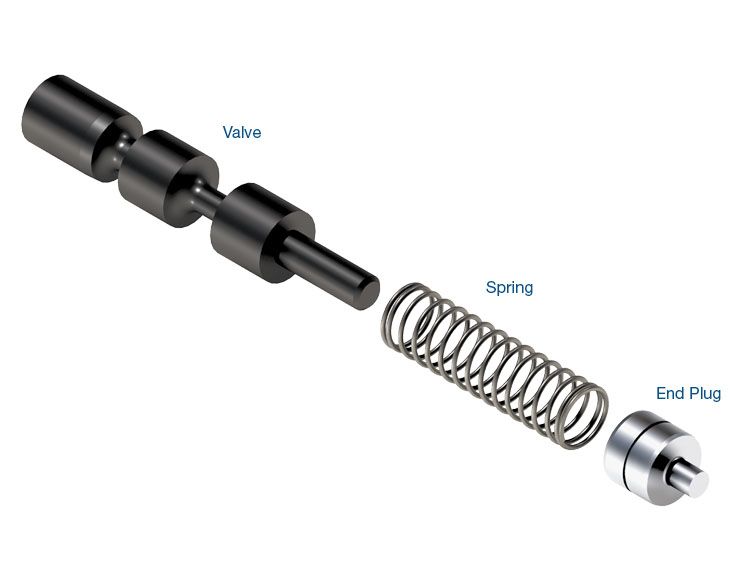

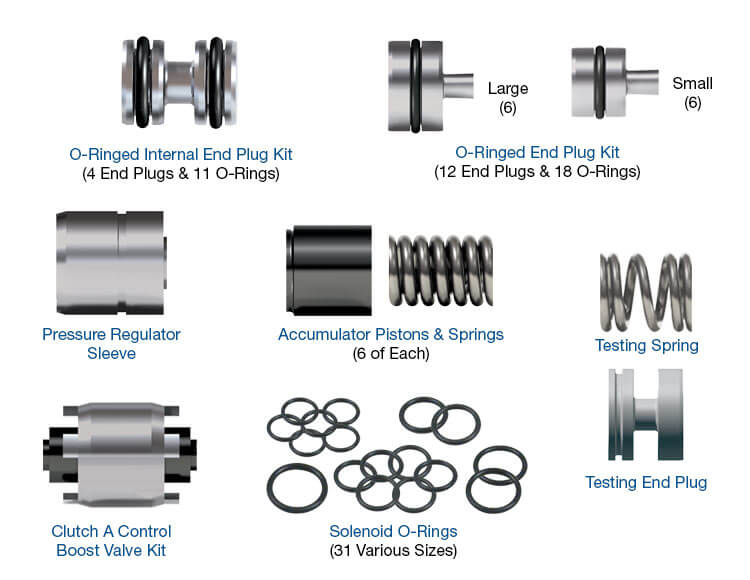

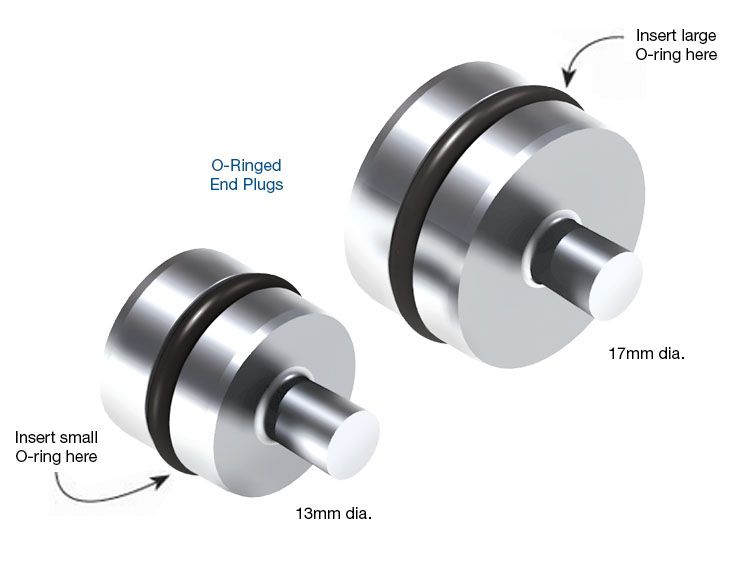

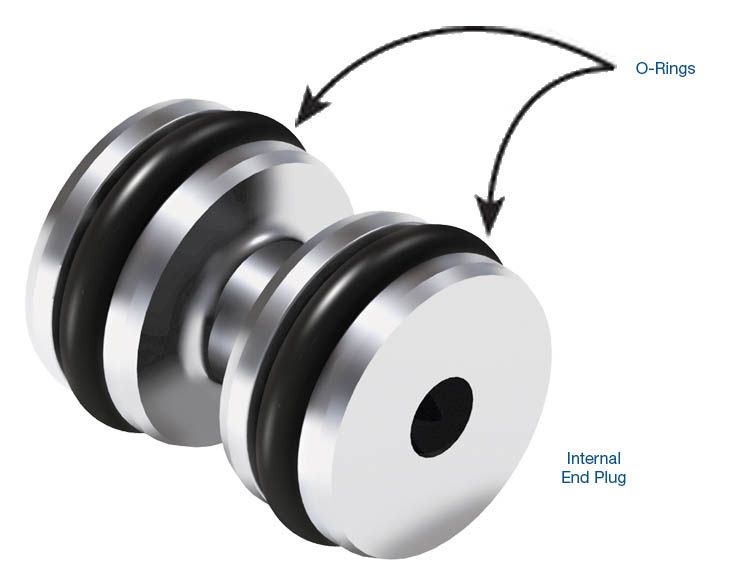

超大转换器释放稳压阀套件95740-05K

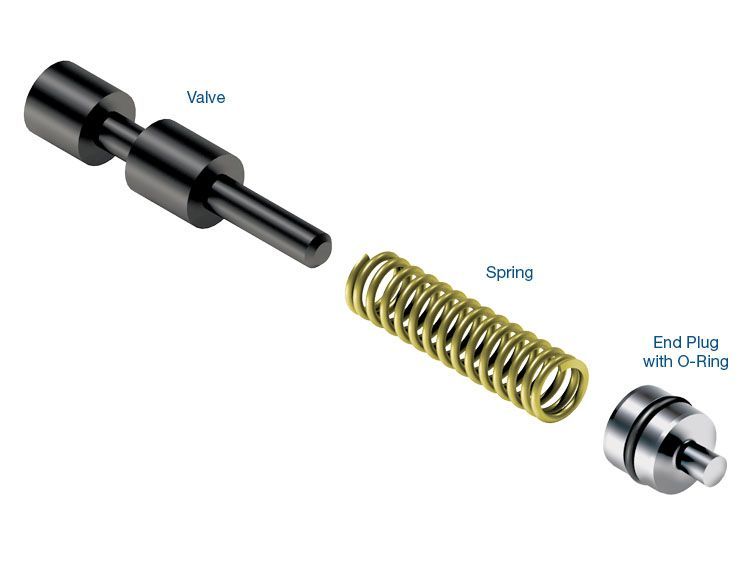

OE valve name: WK-V

-

帮助治愈:

- 多余的TCC滑动RPM和相关代码

- Harsh TCC apply & release

- Low TCC release pressure

- Rough idle in Reverse

- 苛刻的落光

- Flare shifts

- Overheated converter

Required

Recommended

6R100.那6R60.那6R75那6R80 (2009-2014)那6R80(2015年后)那ZF6HP19那ZF6HP26那ZF6HP32

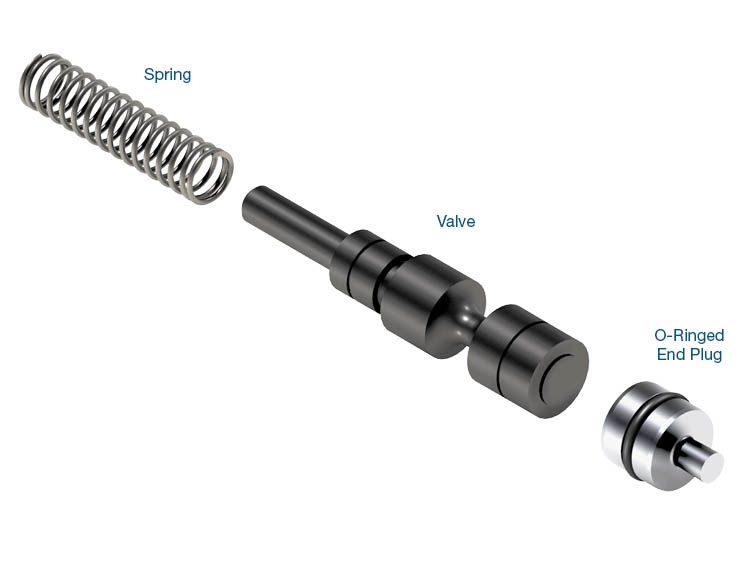

Oversized Lubrication Control Valve Kit95740-11K.

OE valve name: SCHM-V

-

帮助治愈:

- 行星衰竭

- 衬套衰竭

- 润滑油失败

- Overheating

- Low converter pressure

- Bump shifts

- Flare shifts

- Rough idle in Reverse

- TCC适用和释放担忧

Required

Recommended

ZF6HP21那ZF6HP28那ZF6HP34

Oversized Lubrication Control Valve Kit95740-71K

ZF阀名称:SCHM-V

-

帮助治愈:

- Bearing failure

- 衬套衰竭

- 行星衰竭

- 润滑油失败

- Low converter pressure

- Overheating

- TCC代码& concerns

- Rough idle in Reverse

Required

Recommended

6R100.那6R60.那6R75那6R80 (2009-2014)那6R80(2015年后)那ZF6HP19那ZF6HP26那ZF6HP32

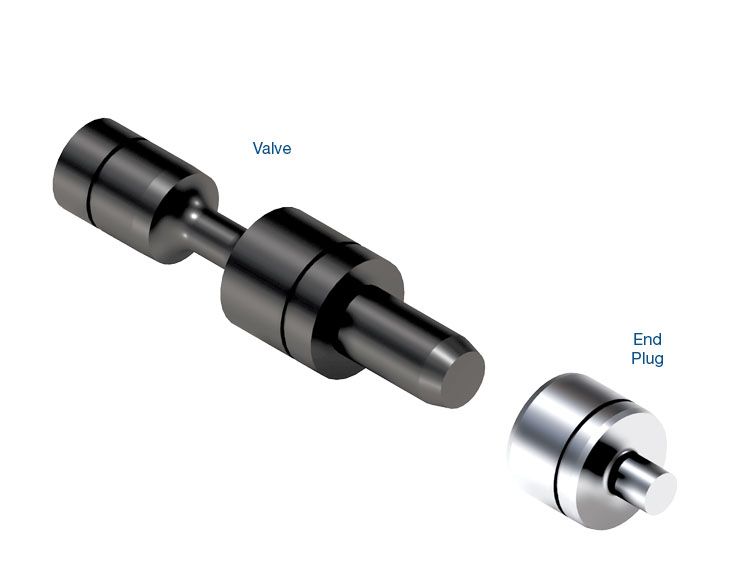

Oversized Bypass Clutch Control Valve Kit95740-13K.

OE阀名称:WD-V

-

帮助治愈:

- TCC代码

- Excess TCC slip

- Cycling RPM

- Low TCC release pressure

- Flare shifts

- 苛刻的转变

- Rough idle in Reverse

- Overheated converter

Required

Recommended

ZF6HP21那ZF6HP28那ZF6HP34

Oversized Bypass Clutch Control Valve Kit95740-73K

ZF阀名称:WD-V

-

帮助治愈:

- TCC代码

- 多余的TCC滑动RPM和相关代码

- Low converter pressure

- Overheated converter

- Flare shifts

- 苛刻的转变

- Rough idle in Reverse

Required

Recommended

6R100.那6R60.那6R75那6R80 (2009-2014)那6R80(2015年后)那ZF6HP19那ZF6HP26那ZF6HP32

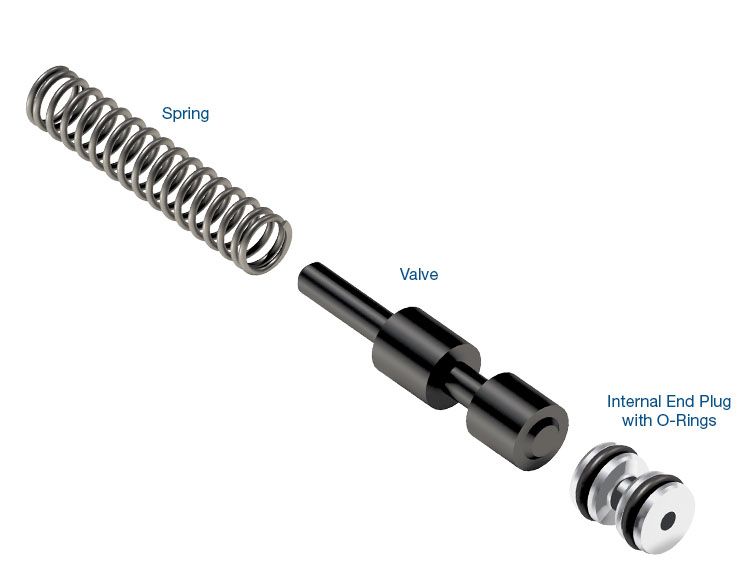

Oversized Solenoid Pressure Regulator Valve Kit95740-17K

ZF阀名称:DR.REO-V

-

帮助治愈:

- Flare shifts

- Neutral shifts

- Harsh upshifts

- 苛刻的落光

- 齿轮比码

- Solenoid performance codes

- Delayed Forward

- Delayed Reverse

- 错误的齿轮开始

- TCC滑倒

Required

Recommended

ZF6HP21那ZF6HP28那ZF6HP34

Oversized Solenoid Pressure Regulator Valve Kit95740-64K

ZF阀名称:DR.REO-V

-

帮助治愈:

- 延迟参与

- Flare shifts

- 苛刻的落光

- Neutral shifts

- High line pressure

- Harsh upshifts

- 错误的齿轮开始

- 齿轮比和螺线管码

- TCC滑倒

Required

Recommended

ZF6HP19那ZF6HP26那ZF6HP32

Oversized Pressure Regulator Valve Kit95740-78K

Fits units with 053 separator plate only.

OE valve name: SYS.DR-V

-

帮助治愈:

- Broken parts due to excessive line pressure

- 不稳定的线压力

- 苛刻的转变

- High line pressure

- Restricted converter/lube flow

- Soft shifts

- Flare shifts

- TCC滑倒

Required

Recommended

6R60.那6R75那6R80 (2009-2014)那ZF6HP19那ZF6HP26那ZF6HP32

Oversized Pressure Regulator Valve Kit95740-01K.

Fits 6R80 '14-earlier. Cannot be used in units that have a 053 separator plate.

OE valve name: SYS.DR-V

-

帮助治愈:

- Poor shift quality

- Flare shifts

- 苛刻的转变

- 不稳定的线压力

- Slips in Forward & Reverse

- Delayed Reverse

- No Reverse

- TCC滑倒

Required

Recommended

ZF6HP21那ZF6HP28那ZF6HP34

Oversized Pressure Regulator Valve Kit95740-69K

ZF阀名称:SYS.DR-V

-

帮助治愈:

- Poor shift quality

- Low line pressure

- Flare shifts

- High line pressure

- 苛刻的转变

- 烧焦换算器

- Delayed Reverse

- No Reverse

- TCC滑倒

Required

Recommended

那6R80 (2009-2014)那6R80(2015年后)那ZF6HP19那ZF6HP26那ZF6HP28

Input/Output Shaft Bushing95030-05

Fits units with .669" (16.98mm) dia. shaft journals only.

- 衬套风格:Precision

- Material:Bimetal

- Housing Bore:0.788“

- Shaft Dia.:0.669“

- Width:0.393"

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

- 比率代码

- B离合器被烧掉了

Required

Recommended

Required

Recommended

Required

Recommended

Required

Recommended

Required

Recommended

Required

Recommended

ZF6HP26那ZF6HP28

Bushing Kit95030-26K

Fits units with input shaft bushing journal diameters of 1.022" (25.97mm) & 1.180" (29.96mm).

- 衬套风格:Precision

- Material:Bimetal

-

帮助治愈:

- E Clutch burned

- B离合器被烧掉了

- 齿轮比和螺线管码

- 衬套磨损

- 衬套衰竭

Required

Recommended

Required

Recommended

Required

Recommended

Required

Recommended

ZF6HP19那ZF6HP21

"B" Clutch Bushing95030-07A

Fits units with 1.219" (30.97mm) shafts only.

- 衬套风格:Precision

- Material:Bimetal

- Housing Bore:1.339"

- Shaft Dia.:1.219"

- Width:0.394"

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

- B离合器被烧掉了

- 比率代码

Required

Recommended

Required

Recommended

ZF6HP19那ZF6HP21

"B" Clutch Bushing95030-07B

仅适用于1.396“(35.47mm)轴的单位。

- 衬套风格:Precision

- Material:Bimetal

- Housing Bore:1.516"

- Shaft Dia.:1.396"

- Width:0.394"

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

- B离合器被烧掉了

- 比率代码

Required

Recommended

ZF6HP19那ZF6HP21

Bushing Kit95030-19K.

- 衬套风格:Precision

- Material:Bimetal

-

帮助治愈:

- E Clutch burned

- B离合器被烧掉了

- 齿轮比和螺线管码

- 衬套磨损

- 衬套衰竭

虽然Sonnax力求确保所以他们racy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.