February 22, 2016

舒适太近:精确定位4L60-E齿轮系组件问题

史蒂夫盖尔特

In Part 2 of this series we will be diving deeper into the workings of one of the automatic transmissions that we introduced inPart 1:4L60。现在我们知道这些单位如何成为的历史,让我们看起来更接近,使他们工作和随着时间的推移而做的改进,使他们更好地工作。

We will start by discussing the first true automatic transmission: the hydraulic planetary automatic transmission. This type of automatic utilizes several planetary gear sets, bands, clutches and a hydraulic system to achieve the different gears. For this example we will use the well-known GM 4L60 (also known as the 700-R4 — the OEM changed the unit name in 1989). This transmission had seven positions on the gear selector: P, R, N, D, 3, 2, 1. These selections were:

Before we dive into the power flow in each gear, it’s important to understand that the power must be transferred from the engine to the transmission. That is where the torque converter (Figure 1)发挥作用。您可以看到每个组件的详细图4L60.298mm torque converter here.

| 图1 - 已合于4L60转矩转换器bob游戏怎么下载 |

|---|

|

The clutch pedal on standards allows the engine to be momentarily disconnected from the transmission to allow the vehicle to travel forward in several gears, travel in Reverse and placed in Park. In the early days of automatics this is where the fluid coupling came into play. A fluid coupling is an oil-filled housing that includes two turbine halves. The cover assembly is attached to the flywheel and spins at the same RPM as the engine. The turbine assembly is splined to the cover, which propels the transmission fluid through the angled fins on the turbine towards the other turbine — the pump — which is splined to the input shaft (Figure 2)。

| 图2 - 4L60转矩转换器bob游戏怎么下载涡轮组件 |

|---|

|

An age-old comparison to show how this process works is to set up two desk fans facing each other and only turn one on. If they are close enough to each other, the air flow from the powered fan will propel the other fan to spin. Much like there isn’t a mechanical connection between the fans, there isn’t actually any mechanical link between the engine and transmission. Fluid couplings were phased out when torque converters were invented.

The difference between a fluid coupler and a torque converter is that a torque converter contains a stator inside the housing. The stator is a cylindrical, turbine-like piece that is installed between the turbine assembly and the converter pump assembly. Its job is to multiply torque by adding another redirection to the fluid path. The fluid now travels from the turbine assembly to the stator assembly, which redirects the oil and changes its direction of rotation to the same as the pump. This redirection increases the force of the oil that is driving the turbine therefore multiplying torque.

After the power is transferred from the engine through the torque converter, it is transferred by the turbine shaft that is pressed into the input housing. The input housing contains the Forward clutch housing, piston, clutch plates, clutch outer race, roller assembly, clutch cam and finally the input sun gear. This brings us to our first planetary set: the input planetary.

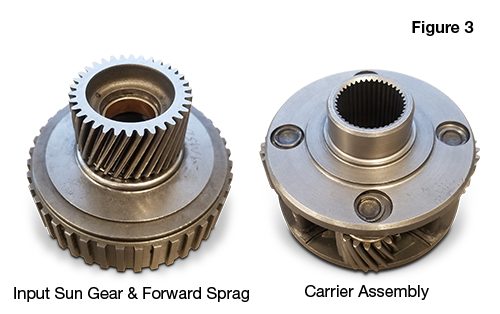

行星齿轮适当命名再保险semble a planetary system. They can be used to increase or decrease the twisting force or torque from the engine. The planetary consists of a center gear called a sun gear, surrounded by pinion gears, which are surrounded by an internal gear. For example, in GM’s 4L60, there are two planetaries: the input (or front) and the reaction (or rear) carrier (Figure 3)。

| 图3 - 4L60输入与反应载体天文 |

|---|

|

来自其他制造商的传输将具有不同的组件和应用每个档的不同方法,但是一般思想仍然是相同的:使用行星齿轮设置以根据负载和速度提供正确的齿轮。让我们看一下4L60(700 r4)的电流。

第一齿轮需要更多的扭矩以使车辆从静止开始移动。这是通过称为减少的过程完成的。在选择驱动范围时,在选择驱动范围时,将前进的离合器施加保持单向低和反向离合器,这防止了反应载体的逆时针旋转,因为它们在一起。反应载体与内部齿轮分开。通过太阳齿轮沿顺时针方向施加电力。

This makes the pinion gears of the input carrier orbit around the sun gear in a clockwise direction while individually rotating counter clockwise. Since the internal gear is restrained from rotating counterclockwise, the input carrier is forced to drive the output shaft which it is splined to. This results in a 3.06:1 torque multiplication and speed reduction. In other words, the input shaft will turn 3.06 times for every one rotation of the output shaft. Combine this ratio with the maximum converter torque multiplication of 2.0:1 and you have a 6.12:1 overall ratio.

当移入第二齿轮时,需要比第一齿轮更少的扭矩和更多速度。仍然施加前进的离合器,但是输入内齿轮和低和反向离合器被释放。反向输入鼓由2-4带保持,这是金属的圆形带,其具有与其结合的摩擦表面。由于逆向输入鼓触及到太阳壳,其与反应太阳齿轮花絮,所以所有三个部件现在将被锁在一起。输入太阳齿轮然后驱动输入载体,输出轴和反应内齿轮。这迫使输入载体通过输出轴将电力传递到反应内齿轮。第二齿轮比最终为1.44:1,因为第二次减少了反应行星。

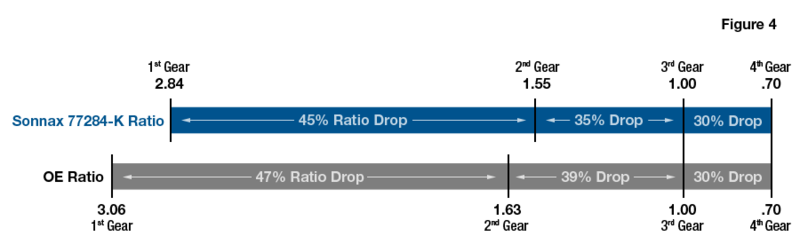

Damage to the band, input/output shafts, sprag, etc. can be lessened by properly cushioning the large ratio change on the 1-2 shift. Reducing the ratio change will improve overall launch in powerful applications, plus reduce stress on band and clutches on the shift by converting 1st Gear from 3.06 to 2.84. Sonnax input carrier kit77284-K是一个独特的齿轮组,完全正确。Figure 4shows the OE torque multiplication factors and ratio changes with an OE reaction carrier vs. the Sonnax carrier.Learn more about cushioning the 1-2 shift ratio change and the benefits of the Sonnax 2.84 gear set in this article.

| Figure 4 – OE vs. Sonnax 4L60 Gear Ratios |

|---|

|

在第三齿轮中,前向离合器保持施加,释放2-4频带,并且施加3-4个离合器。然后电源流过输入外壳,向前离合器,输入楔块和3-4离合器到输入的太阳齿轮。然后,输入行星架在1:1的比率下驱动输出轴,或者是已知的直接驱动。随着速度的增加,需要较少的扭矩,因此需要不同比率。

Fourth Gear, or Overdrive as it is known, is unique in that it is the only overdriven gear. By applying the 2-4 band, the Reverse input housing, input internal gear and reaction sun shell are held similar to 2nd Gear. The difference between 2nd and 4th Gear is that in 4th the 3-4 clutches are applied, which drives the carrier, which in turn drives the internal gear driving the output shaft at a ratio of .70:1. Overdrive still maintains vehicle speed, but improves fuel economy by lowering the RPM of the engine.

Placing the transmission in Reverse activates the Reverse input clutches inside the Reverse input housing, which is tanged to the input housing. The reaction carrier is prevented from rotating clockwise by the Low and Reverse clutches. The power now travels from the converter through the input housing, to the Reverse input housing, to the reaction sun shell, to the reaction sun gear. Since the carrier is being held, the sun gear will drive the reaction carrier pinons counterclockwise on their pins, which drives the reaction internal gear and output shaft counterclockwise at a ratio of 2.30:1.

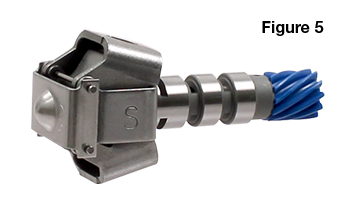

Shift timing in early planetary transmissions is controlled strictly by hydraulic pressure that is supplied by a mechanical governor (Figure 5) that is driven by the output shaft.

| Figure 5 – 4L60 Governor |

|---|

|

The governor is supplied with a constant pressure from the oil pump. When the governor spins at slow speeds, centrifugal force acts on the larger and heavier primary weights first, pushing them outward, which moves the internal valve inside the governor closing the exhaust port and increases the governor pressure. Once the vehicle reaches a speed that forces the primary weights all the way out, they become unable to affect shift timing, which is when the smaller secondary weights come into play. Because of their smaller weight, they are less affected by centrifugal force and provide the smaller adjustments at higher speeds.

现代传输依赖于电子速度传感器和车辆的节气门位置传感器,以向传输控制模块(TCM)提供发动机负载信息。

While the governor controls the timing of the shifts, the hydraulic system is responsible for applying the clutches and bands. The heart of the hydraulic system is the pump, which is keyed to the converter pump hub and turns when the engine is running. The pump in a 4L60 (700-R4) is a rotor-and-vein-style and provides the necessary line pressure to the hydraulic system to apply the bands and clutches.

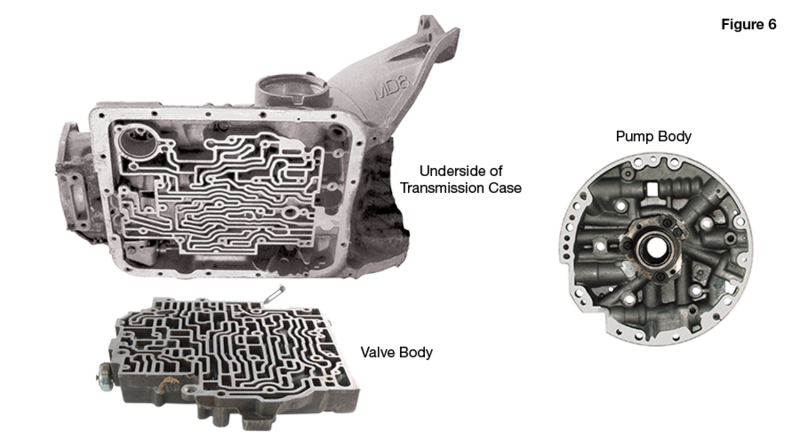

前面提到的齿轮选择器允许the driver to select the desired range is connected to the manual valve inside the valve body. The manual valve directs the fluid path from the pump to the valves of the valve body. The valve body is a complex assembly of interconnected fluid paths, precision valves, checkballs and orifices (Figure 6)。

| Figure 6 - 4L60 Valve Body & Pump |

|---|

|

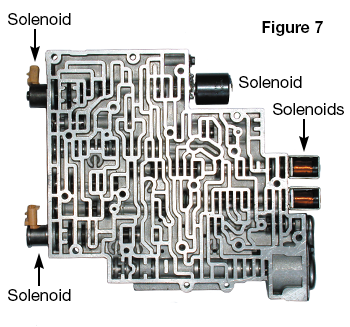

In older units, the valve body would utilize a valve for each specific gear change, called a shift valve. Each shift valve when stroked in the correct direction completes the fluid path necessary to activate the clutch pack(s) and/or band to achieve the appropriate gear. In modern transmissions such as the successor to the 4L60 — the 4L60-E (Figure 7) — gear changes are achieved electronically, instead of hydraulically, by using solenoids.

| Figure 7 – 4L60-E Valve Body with Solenoids |

|---|

|

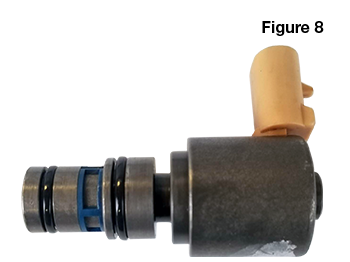

螺线管(Figure 8) is an electromagnetic valve that can be opened or closed by applying voltage across the solenoid coil by the transmission control module.

| Figure 8 – 4L60-E Solenoid |

|---|

|

离合器的实际应用程序包或乐队is accomplished by using pistons and servos. These are devices that convert hydraulic pressure into mechanical force to provide the clamping force necessary to hold the band or clutches without slippage. Stock and aftermarket servos come in different sizes to deliver different degrees of holding power.在本科文章中了解更多关于4L60-e伺服选项的更多信息.

While the main principles of the hydraulic planetary transmission have remained mostly unchanged since transmissions like the 4L60 (700-R4), improvements had to be made to increase fuel efficiency to meet the demands of tightening emissions. As covered inThe Evolution of Automatic Transmissions Part 1: A Brief History, manufacturers accomplished this by adding additional gears. Using General Motors as an example, for the front-wheel-drive platforms they went from the 4-speed 4T40-E and 4T65-E to a 6-speed 6T70 in 2007 for V-6 applications and 6T30/40 in 2008. For the rear-wheel-drive platforms, they started upgrading the 4-speed 4L60-E to 6-speed 6L80 in 2006, then to the 8-speed 8L90 in 2014 and finally to the 10-speed 10L90 in 2017. Other manufacturers of course followed a similar path of progression of adding gears to improve vehicle efficiency.

Jason Larchelle是Sonnax产品支持代表。他是Sonnax的成员TASC Force(技术汽车专业委员会),一批认可的行业技术专家,传输重建者和Sonnax技术人员。

February 22, 2016

史蒂夫盖尔特

March 02, 2016

2月26日,2021年

格雷格·纳米德

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.