Bushwhacked! Keys to Avoiding Preventable Bushing Problems

Brian Wing

衬套在自动变速箱中始终发挥着重要作用。我们都看到了涂抹衬套的后果,我们已经取代了损坏的衬套和乘坐它们的组件,并在重建期间更换预防性套管是常见的。通常,作为技术人员,我们通常不会思考衬套,直到我们遇到一个被烹饪的人。关于衬套的重要因素,我们大多数人在衬套选择和安装期间不考虑;考虑到这些因素是确保所有构建中的长期无故障套管性能的基础。

曾经想过为什么一些传播似乎有衬套比其他人疲惫不堪?由于衬套失败了卷土重来?是什么导致衬套失败了?当然,一些问题是由润滑油供应或未对准的部分减少引起的,但存在衬套失效的其他可预防原因,以及我们如何最小化被扣除或纺纱衬套或衬套相关的失败燃烧的机会。在我们的情况下保修期?With a bit of insight into bushing purpose, design and most-favorable operating characteristics, it is possible to lengthen bushing life, improve fuel economy and keep the gear train properly aligned so that other (seemingly) non-related components don’t wear out prematurely and result in a comeback.

Only the Strong Survive

To work successfully and live a long life, bushings in automatic transmissions need to be designed within the following general parameters:

- 必须支持齿轮和旋转部件产生的大型力 - 负载高达1,400 psi

- Must handle speeds of up to 9,500 RPM (top planetary speed)

- Must endure temporary operation with low/no lube oil

- 由于制造异常,必须最小化由于摩擦而导致的拖曳/热/功率损耗和“关闭”条件(例如组件未对准)

- 必须为支撑轴提供最佳间隙,以便在衬套和轴期刊之间实现适当的流体膜厚度

- 必须能够密封电路(必填)

- Must resist corrosion

With these constraints in mind, design engineers have a raft of items to consider in their effort to produce a bushing that can stand up under punishing conditions.

Bushing Design: The Engineer’s Dilemma

在设计过程中,衬套材料选择是第一代价,工程师必须思考。基于最理想地适合预期应用的特性选择材料。但是,所有材料选择都是妥协;每个材料具有不同的属性,并且一种材料可以更适合于特定应用。在自动传输中,必须考虑以下材料属性:

- 疲劳抵抗— The greater load-carrying capacity a material has, the greater its resistance to fatigue.

- 得分和癫痫发作- 材料抵抗探测和焊接到配合组分的能力,特别是在低或无油状下。

- Conformability— The ability of the material to compensate for component misalignment and deflection.

- Embedability- 材料吸收和螯合悬浮在ATF中的外来颗粒的能力。

- 耐腐蚀性能— The ability to withstand corrosive media that develops in ATF over time.

任何工程师都希望在所有这些领域的高度高度率的材料,这是不可能的;必须进行权衡。有四种一般材料类别可供选择,每个类别都有许多可能的基础材料组合:

- 铅/锡基巴巴特— Relatively soft; poor fatigue resistance, which worsens with increased temperatures. Excellent conformability, embedability and seizure resistance. Good corrosion resistance.

- Copper/Lead (Bronze)- 高疲劳性;略低于较低的符合性,可造型和癫痫发作量比Babbitt。公平的耐腐蚀性。

- 铝制/锡,铝制/硅,铝制/铅- 高疲劳性;混合得分和癫痫发作;适当性和既定尺寸远低于巴比特和青铜。优异的耐腐蚀性。

- Polymer-Impregnated Bronze (PTFE)- 良好的疲劳性;出色得分和癫痫发作;一致性非常好,可抵御性低于青铜。优异的耐腐蚀性。低油条件的大公差窗口。

无论哪种材料选择,大多数套管都将设计有钢背衬,以便在壳体孔中最佳地保持。钢板还增加了疲劳性能和易于安装。如果没有结合钢板,则不仅可以保持耐受,套管通常可以在安装力下扭曲,并且可能导致配合轴的配合问题。目前最常用的材料是钢板背铜,铝和PTFE。

重要的材料说明

铝衬套有一层薄薄的锡,硅or lead on the load-bearing surface. While this surface provides excellent anti-score and anti-seize properties, it is very easy for that layer to be damaged in a heartbeat during low- or no-oil situations which commonly occur in transmissions. When that happens, the aluminum material that is exposed to the riding shaft fails by seizing very rapidly. Thus, aluminum bushings are not a good idea for areas where lubrication is not immediately and continuously available.

第二章涉及PTFE-coated与ptfe-impregnated衬套:制造方法使得良好的衬套和一个可能失败的灾难性之间的差异。对于这些衬套有效,必须将PTFE层烧结(浸渍)进入青铜中间层,具有钢板。烧结在青铜的整个结构上完全扩散了PTFE分子,在原子水平上锁定它们。如果PTFE层未烧结 - 即,采用粘合剂或热喷涂以将PTFE连接到衬套上 - PTFE层通常在操作期间从背衬中分离或去粘合,允许癫痫发作。PTFE基金会类似于我们的下巴 - 没有良好的根,我们会失去大量的牙齿。

轴直径,壁厚和倒角

当然,轴直径当然是衬套设计的键输入。支撑轴,壁和长度之间的比例关系总是需要。因此,不紧密控制的壁厚可以导致衬套ID与轴不良好地交配,允许组件的未对准和可能的润滑性问题。壁厚对于壳体轴承保持轴承也很重要。

为了便于安装,需要指定角度的OD和ID倒角。它们将衬套引导到孔中,轴进入套管。如果任何这些因素都被错误地指定或不考虑,则将产生较低的衬套。

Is This Thing Groovy, or What?

凹槽或不沟槽是一个重要的设计考虑因素。套管ID中的凹槽并不总是使用,但它们在许多应用中使用以改善润滑(Figure 1).

| 图1 - 带凹槽的衬套 |

|---|

|

Groove design can be very complicated, but basically depends on lubricant type, source and quality as well as operating conditions and bushing dimensions. Grooves are also often used as a pumping mechanism, whereby the spinning shaft pumps oil through the bushing groove to lubricate the bushing and/or the component beyond the bushing.

在许多应用中,不活动时段允许大部分ATF从衬套中消失。在这些情况下,球凹口可以被卷入衬套表面,其充当小型油藏。这些水库在启动期间将润滑可用于衬套,直到正常润滑恢复(图2)。

| Figure 2 — Bushing with Indentations |

|---|

|

衬套和配合轴饰面

衬套和/或配合轴上的过度粗糙是衬套磨损和最终故障的主要原因。工程师可以控制衬套的表面光洁度,但它将与另一个问题一起使用的轴。为了获得最佳结果,衬套的负载表面应小于25微英寸的RMS,而轴期刊应为8-12 rms。由于负载能力与轴表面光洁度直接相关,因此在防止衬套的过早磨损的同时,将施加疲劳阻力。

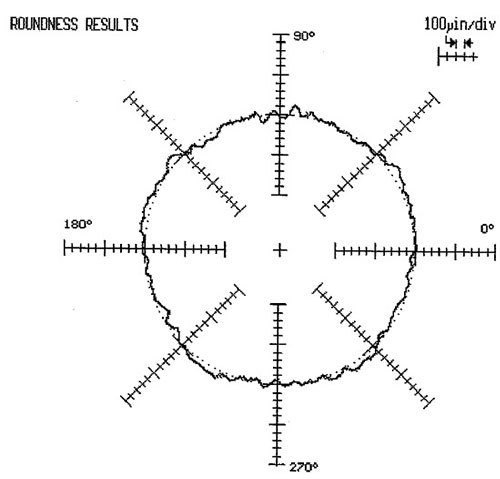

轴轴颈可以具有可接受的表面,但由于杂志表面的过量“波纹”,仍然磨损衬套。该波纹也称为研磨颤振,并且在制造研磨过程中发生。图3.shows a measuring micro-trace of a 4L80-E main shaft journal that caused bushings to wear out rapidly and repeatedly; quickly prepping this shaft by minimizing the chatter ridges restored normal operation.

| 图3. |

|---|

|

Though the design of a bushing is considerably more complex than the basic information laid out here, we now have a general picture of the main considerations involved in producing a quality bushing. However, no matter how good the bushing design and manufacture might be, it cannot operate successfully unless the environmental conditions it will live in are favorable. The torch is now passed to the bushing installer.

逃避杀戮区

以下建议将在您在保修期内遇到令人惊讶的衬套攻击的机会:

- Realize that worn (or poorly made) bushings are the cause of problems from circuit leaks to component misalignment, clutch failure, broken components, friction losses, etc.

- Ensure the lubrication circuit operates normally. Vacuum test appropriate control valves and replace with oversized as necessary. Ensure lube passages are unrestricted.

- 选择替换衬套时,选择具有良好公差规格的声誉的制造商,因为轴向衬套间隙是润滑膜厚度和部件对准的关键。这对于使用套管来密封电路的部分来尤其重要。衬套密封电路的一个例子是ZF6HP单元中的“E”离合器的实例;我们大多数人现在都熟悉驾驶性问题和4F85比率监控代码这些单位当后定子衬套磨损时抛出。因为OE衬套在这些ZF应用中利用了较好的材料,所以这会发生这种情况。

- 在大多数情况下,忘记不支持钢铁的衬套。安装过程中较低的疲劳电阻,降低,保持性能和变形的可能性使得非钢背衬套对于许多应用来说是过度危险的。

- 将衬套安装到铝制外壳孔中时,在安装前夹持衬套倒角的前缘。这将防止粘附铝孔。

- If you use a driver and hammer to install bushings, a change of practice is recommended. We’ve all done it — and gotten away with it many times — but the fact is that precision bushings can distort when driven in, causing fit and performance issues. Shock loads from driving tend to deform bushings (some more than others). Instead, always use an arbor press, which protects and preserves the integrity of the bushing ID and chamfers. Purchase or make dedicated bushing installers to use with the arbor press; replace any of these if they get dinged or scratched. Lightly lube the bushing before pressing.

- 对于处理高负载的衬套,用套筒再保险tainer or carefully stake them in after installation to prevent possible spinning.

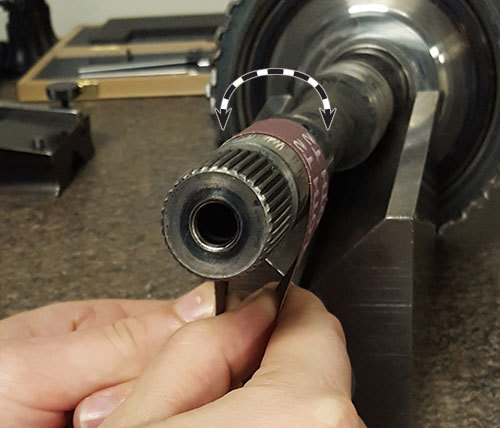

- 在安装之前准备轴期刊和外壳孔。为了最佳保留,壳体孔可以完成为60-125微英寸rms。对于轴期刊,最佳饰面是8-12 rms。您可以用适当的砂砾砂布用手轻易做到这一点;60个砂砾将在外壳中工作,400个砂砾将在轴期刊上掉线(Figure 4)。

图4.

| Grit Size | rms(微英寸) |

|---|---|

| 36. | 160. |

| 60 (Use on Housing) | 98 |

| 120. | 58. |

| 180. | 34. |

| 240. | 17. |

| 320 | 14. |

| 400 (Use on Shaft) | 10. |

- We’re not trying to remove material here, so keep a light touch and just kiss the surface to get the best results. For the shaft, rotate the emery cloth back and forth around the axis of rotation(图5)。

| 图5 - 带砂布的准备轴日志 |

|---|

|

- 别忘了清理所有润滑洞和段落。图6.显示一个预制和一个非预洗轴。您希望在您的构建中安装哪一个?

| 图6 - 预制轴与非预制轴 |

|---|

|

- Always use manufacturer-recommended oil, which the bushing was specifically designed to be run with. The right oil must be used to maintain the desired oil thickness between bushing and shaft, and to protect the shaft as it spins.

- Dirt is the worst enemy of a bushing. Be relentless about keeping the unit clean during service.

- 确保所有底盘场都完整并清洁,电压下降不稳产。如果由于设计路径中的电阻过多,电压无法接地,它将找到另一种方式来实现此处的衬套。

另一个子弹躲过了

衬套只是在任何重建期间竞争我们注意的许多东西之一;当我们试图追踪完全无关的问题的原因时,可以很容易地忽略他们的重要性。但它会始终记住他们在每一个都玩的重要角色传播that comes across your path, regardless of the reason it is on the bench. Selecting the highest quality bushing available for your application, taking the time to prepare the mating shaft/housing bore and using preferred installation methods are fundamental steps in your never-ending quest to fend off prematurely worn bushings and bushing-related comebacks.

Brian Wing是Driveline和传输组件的Sonnax产品开发经理。bob综合体育下载他是Sonnax的成员Tasc力量(Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

Related Units

Related Parts

必需的

Recommended

F4A41/42/51那F5A51.那R4/V4A51那R5A51那V5A51

Pump Bushing41005-01

- 衬套风格:Precision

- 材料:钢底双金属

- Shaft Dia.:1.691"

- Width:0.545"

- Housing Bore:1.810“

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

必需的

Recommended

MD 3000系列

Pump BushingS29524335

- 材料:Bimetal

- 衬套风格:Precision

- Housing Bore:2.517"

- Shaft Dia.:2.246"

- Width:0.680"

必需的

Recommended

必需的

Recommended

必需的

Recommended

必需的

Recommended

必需的

Recommended

必需的

Recommended

必需的

Recommended

必需的

Recommended

4L60那4L60-E那4L65-E.那4L70-E.

Wide Reaction Sun Gear Bushing77010-01.

May not work in some late-production sun gears with OE finish-in-place bushings.

- 材料:Steel-backed bronze

- 衬套风格:Precision

- Housing Bore:1.706"

- Shaft Dia.:1.575“

- Width:0.600"

-

帮助治愈:

- 衬套衰竭

- 反应载体轴损坏

必需的

Recommended

必需的

Recommended

必需的

Recommended

180.C (3L30)那4L30-E.那AR25那AR35.

钟外壳衬套54253-01

- 衬套风格:Precision

- 材料:Steel-backed aluminum

- Width:0.560“

- Shaft Dia.:1.874"

- Housing Bore:2.003"

-

帮助治愈:

- Leaking front seal

- 衬套磨损

必需的

Recommended

MD 3000系列

Pump BushingS29533975

MD / B 300 / B 400,T200 / 300系列,带有和没有PTO

- 材料:Bimetal

- 衬套风格:Precision

- Housing Bore:3.186“

- Shaft Dia.:2.952"

- Width:0.718“

必需的

Recommended

必需的

Recommended

HD 4000系列

Pump BushingS29527102

Early design, HD4000

- 材料:Bimetal

- 衬套风格:Precision

- Housing Bore:2.944"

- Shaft Dia.:2.625"

- Width:0.700"

必需的

Recommended

4F27E.那FN4A-EL那FNR5.那FS5A-EL

Stator Bushing46000-01K

- 衬套风格:Precision

- 材料:Bimetal

- Housing Bore:0.867"

- Shaft Dia.:0.747“

- Width:0.266“

-

帮助治愈:

- High TCC slip RPM (TCCMACT) increases with operating temperature

- Code P0741

- 衬套衰竭

- 衬套磨损

- Overheating

必需的

Recommended

722.6

Rear Pump Stator Bushing68915-01

- 材料:Bimetal

- 衬套风格:Precision

- Housing Bore:1.358“

- Shaft Dia.:1.239“

- Width:0.420"

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

必需的

Recommended

4L80-E.那4L85-E

Stator Support Bushing34016-W.

- 衬套风格:Precision

- 材料:钢底双金属

- Width:0.675“

- Shaft Dia.:1.123“

- Housing Bore:1.244“

-

帮助治愈:

- TCC滑动码

- 没有锁定

- 过热的流体

- 没有过载

必需的

Recommended

350C.那4L60那4L60-E那4L65-E.那4L70-E.那PowerGlide.

Stator Support Bushing35007A

- 衬套风格:Precision

- 材料:钢底铜合金

- Width:0.500“

- Housing Bore:1.121"

- Inner Dia.:1.004“

- Shaft Dia.:1.002“

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

必需的

Recommended

必需的

Recommended

4L60那4L60-E那4L65-E.那4L70-E.

Rear Stator Support Bushing77002B

- 衬套风格:Precision

- 材料:Steel-backed lead/bronze alloy

- Width:0.510“

- Inner Dia.:1.250"

- Housing Bore:1.360"

- Shaft Dia.:1.237“

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

必需的

Recommended

必需的

Recommended

722.6

Pump Bushing68004-02

完成。超大的O.D.也适合722.3和722.5单位。

- 材料:Bimetal

- 衬套风格:finish

- Width:0.550"

- Shaft Dia.:1.678"

- Housing Bore:2.000“

-

帮助治愈:

- 套管旋转在外壳

- Pump leaks

- 泵损坏

必需的

Recommended

AL-4那DPO

E1 / E2离合器鼓衬套120002

E1 / E2离合器鼓

- 衬套风格:Precision

- 材料:钢板铝合金

-

帮助治愈:

- 烧伤的离合器

- 多余的轮毂到衬套清除

- 第二品质差

- 第二次不稳定

必需的

Recommended

722.6

Input Shaft Bushing68410-01.

- 材料:Bimetal

- 衬套风格:Precision

- Housing Bore:1.023"

- Width:0.446“

- Shaft Dia.:0.906"

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

必需的

Recommended

必需的

Recommended

必需的

Recommended

必需的

Recommended

必需的

Recommended

必需的

Recommended

必需的

Recommended

HD 4000系列

Pump BushingS29542029.

Late design; HD4000

- 材料:Bimetal

- 衬套风格:Precision

- Housing Bore:2.878"

- Shaft Dia.:2.623"

- Width:0.700"

必需的

Recommended

722.6

Pump Bushing68004-01

Fits '96-later

- 材料:Bimetal

- 衬套风格:Precision

- Housing Bore:1.810“

- Shaft Dia.:1.692“

- Width:0.550"

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

必需的

Recommended

A6MF1 / 2.

Pump Bushing10.2034-01

泵,钢背用球腺

- 衬套风格:Precision

- 材料:钢底双金属

- Width:0.520“

- Shaft Dia.:1.693“

- Housing Bore:1.831“

-

帮助治愈:

- Pump bushing & mating impeller hub wear prematurely

必需的

Recommended

必需的

Recommended

AL-4那DPO

Pump Bushing120001

- 衬套风格:Precision

- 材料:钢板铝合金

- Width:0.533"

- Shaft Dia.:2.142“

- Housing Bore:2.241“

-

帮助治愈:

- Leaking front seal

- Low pump volume

- 延迟参与

- 转换器颤抖和TCC滑动

必需的

Recommended

ZF6HP26那ZF6HP28

Bushing Kit95030-26K

配合输入轴衬套轴颈直径为1.022“(25.97mm)&1.180”(29.96mm)。

- 衬套风格:Precision

- 材料:Bimetal

-

帮助治愈:

- E Clutch burned

- B离合器被烧掉了

- 齿轮比和螺线管码

- 衬套磨损

- 衬套衰竭

必需的

Recommended

ZF6HP19那ZF6HP26那ZF6HP28

Rear Stator Support Bushing95030-01.

适合1.022“(25.97mm)Dia。输入轴期刊。

- 衬套风格:Precision

- 材料:Steel-backed alloy

- Width:0.590“

- Housing Bore:1.142"

- Shaft Dia.:1.022"

-

帮助治愈:

- E Clutch burned

- 齿轮比和螺线管码

- 衬套磨损

- 衬套衰竭

必需的

Recommended

ZF6HP19那ZF6HP21

Front Stator Support Bushing95030-09.

适用于.952“(24.17mm)直径输入轴前台。并非所有ZF6HP19 / 21单位都使用前定子支撑衬套;必须在安装前验证应用程序。

- 衬套风格:Precision

- 材料:Bimetal, aluminum alloy lining

- Housing Bore:1.063“

- Shaft Dia.:0.952"

- Width:0.393“

-

帮助治愈:

- 衬套磨损

- 衬套衰竭

- Damaged converter

必需的

Recommended

必需的

Recommended

虽然Sonnax尽一切努力确保在出版时确保技术文章的准确性,但我们对不准确或可能过时或过时的信息不承担任何责任。