2013年1月19日

阀体资格

Bob Warnke

考虑到透速维修的高成本,有效诊断的价值从未如此高。真空测试已成为识别阀体问题和验证维修的可信方法。当技术人员可以很好地了解它的工作原理和泄漏的传输组件来轻松地将此诊断工具扩展到其他区域。(在本文末尾观察视频,以便在行动中进行4L80-E超常离合器真空测试的演示!)

The Origins of Valve Body Vacuum Testing

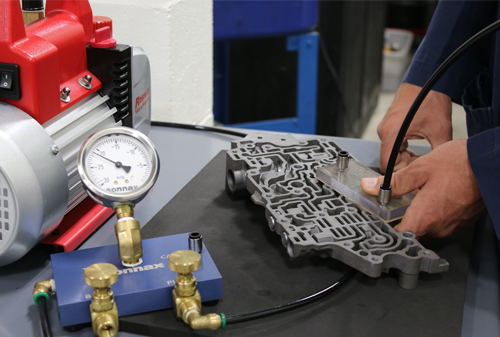

Transmission testing methods over time were forced to evolve and change due to increasingly complex components, especially for testing valve bodies. Many years ago at Sonnax, we recognized there were challenges in accurately diagnosing wear in the newer, lightweight valve body assemblies. Wear of the valve bores and on the valve spools created shift control issues. These issues were also dependent on whether the oil was thick (cold) or thin (hot). Conventional testing at the time was wiggle testing, wet air testing, flashlight testing and bore mic testing. These early practices did not give reliable results with the newer, thinner and more lightweight fluids. Technicians needed more accurate tests to get consistent and repeatable results. It was critical to have the ability to measure wear inside hydraulic control units and be able to retest after repairs to confirm results.

制定真空测试阀体以满足这一挑战,因为它允许技术人员分配与阀孔区域中泄漏的可量化值。该方法已经被发动机制造商使用,以测试泄漏阀,阀座和导向器。将真空测试应用于阀体,提供了成本效益,可重复的方法,并具有记录的数字的精确答案。

|

| 阀体真空测试 |

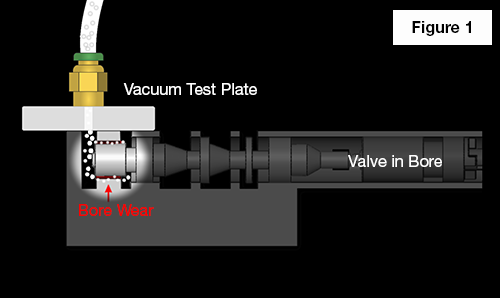

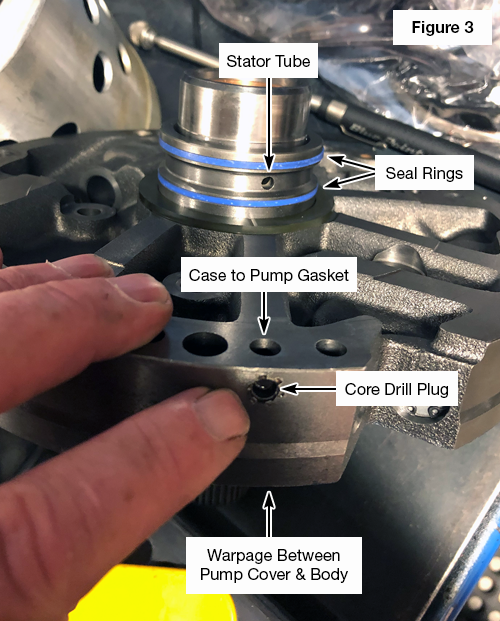

How it works: an electric vacuum pump is used to pull a constant vacuum through the space between the casting bore and the outer diameter of the spool (Figure 1)。The vacuum value for the valve-to-bore clearance can then be read on a calibrated gauge (Figure 2)。这种新的测试方法从决定磨损中汲取了猜测,并且被发现准确,适用于轻型磨损和高里程的铸件,旧和新的。

| 图1 -阀门Body Vacuum Testing |

|---|

|

| 图2 - 真空测试结果 |

|---|

|

Sonnax understood how valuable this test method could be to shops and took to the road to teach just how simple it was. Through the Sonnax Roadshow, technicians learned how to test and diagnose valve bodies and, when needed, make repairs. They were now able to verify that a repair or replacement was needed based on measureable results. Check out theSonnax路演要查看一些有助于使用测试阀体的视频。

It’s Time to Go Beyond Valve Bodies

用于测试阀体的相同真空测试方法也可以用于其他传动部件和密封的容纳区域,例如保持制动器和离合器鼓。这些区域的现代传输比老单在这些区域都易于泄漏。F型和DEX流体,自动变速器中使用的第一流体将分解并创造清漆积聚。这种清漆实际上在液压系统中密封泄漏,并且在制造过程中允许放松加工公差。不幸的是,清漆还填充了摩擦材料的毛孔,当施加离合器包装时,不能挤出厚糊状的液体,导致钢板或鼓溅射。

现代传动液不会造成大量清漆,因此不要像较旧的液体一样密封泄漏,因为它们崩溃了。传输内的泄漏产生热量,导致扩展增加,这反过来又会产生更大的泄漏。这些泄漏可以负责举起遏制区域的备考,耗尽润滑油并防止其达到目的地,最终导致齿轮,带和离合器故障。以下是某些区域可能导致昂贵的重复故障,可以诊断为真空测试:

And many more!

Let’s look at a few simple vacuum tests that can put a specific value to leakage in an assembly — leaks that a conventional air test won’t find. These vacuum tests, along with proper air testing, help prevent comebacks. An important lesson I have learned is that the goal in testing is not to place blame on a component, but to rule out what you know is NOT causing the issue to more easily find what IS causing failures.

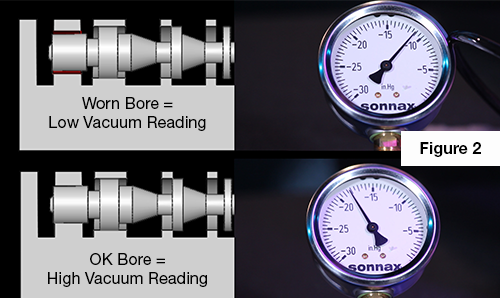

你需要记住在测试是“石油= oil out.” During a rebuild on a 4L80-E (based on failed components) the feed circuit that directs the supply of oil to the overrun clutch may be an issue, and confirming that it is ok becomes important (Figure 3)。与此单位的故障导致需要维修的是“超级离合器被烧毁,过驱动滚子离合器失败。”这两个故障创造了这一点,没有向前且没有反向运动。

| Figure 3 – Potential Leak Areas |

|---|

|

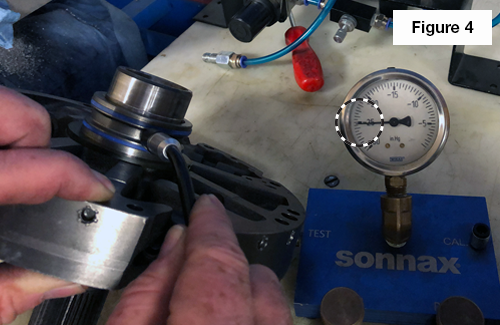

The first test checks for leaks where the core drill plug that is used to block the passage from a core drill and where the stator tube presses into the cover. Plug the top and bottom casting drill/oil delivery passage with your fingers and insert rubber-tipped test tube into stator tube hole (图4). Results with gauge must show zero leakage with 25 in-Hg on vacuum test gauge (if 25" is the seal-off number when calibrated).

| 图4 - 核心钻头和定子管测试 |

|---|

|

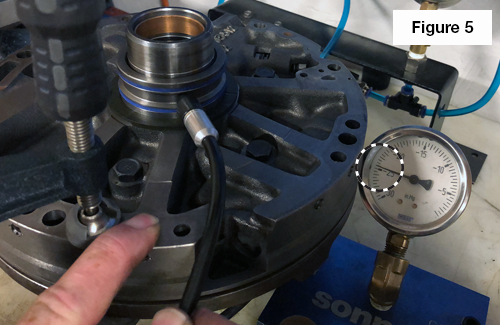

Leakage also can happen due to warpage in the pump as assembled cover to body, so the second test is done with the pump assembled (torqued together). When assembled, install a clamp to ensure outer edges are tight. Plug feed hole with finger and vacuum test on the stator tube hole between seal rings with rubber-tipped test tube. Test results should not drop more than 1" of vacuum on the gauge. If it drops more than this, the pump should be surfaced to prevent failure. As shown inFigure 5, the original test on just the cover was 25 in-Hg and now, bolted together, we found only a little leak with results at 24 in-Hg. This is OK because it’s not more than 1" of difference. Any greater than 2" and you should try to isolate where the leak is. This may include surfacing both sides of the pump and cover.

| 图5 - 翘曲测试 |

|---|

|

We will keep writing and illustrating different test procedures in future articles so keep your eyes open. If you are having issues with any tests and circuits, please let us know by contacting us atbob app下载 . Until then, keep those transmissions healthy.

Randall Schroeder is a Sonnax technical sales and training specialist. He is a member of the SonnaxTASC Force(Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

2013年1月19日

Bob Warnke

January 22, 2011

2015年1月5日

2015年1月5日

2015年1月5日

September 12, 2017

Randall Schroeder

必需的

Recommended

虽然Sonnax尽一切努力确保在出版时确保技术文章的准确性,但我们对不准确或可能过时或过时的信息不承担任何责任。