March 02, 2016

Guard Against 4L60/E Band & 3-4 Clutch Failure: Test the 3rd Accumulator Checkball Assembly for Leakage

Gregg Nader

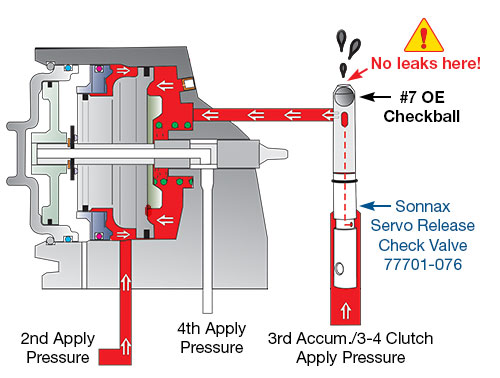

In 4L60-E, 4L65-E and 4L70-E units, it’s crucial to prevent even minor leaks in the 3rd accumulator checkball assembly. Leakage at the hidden #7 checkball (Figure 1) reduces 3‐4 clutch apply pressure, a direct cause of burnt 3‐4 clutches. Leakage also reduces band release pressure, allowing the band to drag when it should be released, leading to burnt 2‐4 bands.

| 图1: 2-4 Servo Assembly Cross Section |

|---|

|

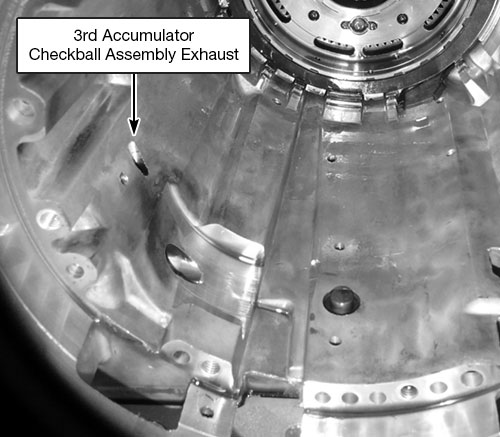

If you have the equipment available,vacuum testingwith the Sonnax vacuum test stand kitVACTEST-01Kis the quickest and most effective way to verify that the #7 checkball is sealing. With a soft rubbertip, vacuum test at the location shown (Figure 2). Results should be a near perfect seal.

Another way to check for leakage is to position thetransmissionhorizontal on the bench with the pan side up. Drip solvent into the 3rd accumulator checkball assembly and watch for solvent leakage on the inside of the case at the location shown (Figure 2).

| Figure 2 |

|---|

|

|

Test for leakage at the 3rd accumulator checkball assembly exhaust hole. The smaller hole beside it is the bleed orifice that sprays oil onto the band and drum surfaces.

|

If leakage is detected with either of these methods, try re‐seating the checkball with a punch and light tap with hammer, then test again. If leakage persists, remove and replace the 3rd accumulator checkball assembly.

Note:Don’t confuse the OE capsule with the Sonnax servo release check valve kit capsule (77701-076). Although they look similar, they have completely different functions. The Sonnax valve is a unique solution that combines an orifice with a ball check valve to tune 3-4 shifts, but it MUST be used with a properly functioning OE capsule.

Gregg Nader is a Sonnax product development manager for high performance and heavy-duty transmission components. He is also a member of the SonnaxTASC力(Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.

Learn More

Related Units

Related Parts

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.