电磁性能故障诊断s in A761, AB60 & A960 6-Speed Transmissions

吉姆拨打

Toyota / Lexus A761,AB60和A960 6速度传输在过去几年中更频繁地在商店中出现。担保是到期的,这些天似乎人们似乎挂在他们的车辆上。即便如此,这些变速器也有许多不同的问题,包括与AB60 TUNDRA应用特别慢性的变矩器离合器故障。bob游戏怎么下载所有这些单位的共同点是一个问题,它比其他问题更加粘在一起,但是:开关电磁阀机械故障码。您将通过P0751 S1电磁阀性能,P0756 S2电磁阀性能,P0761 S3电磁阀性能和P0766 S4电磁阀性能码。

These types of Diagnostic Trouble Codes (DTC) set when the Transmission Control Module (TCM) commands a specific gear and an incorrect ratio is shown from the input and output speed sensors. As an aid for diagnosis, the TCM will set a DTC related to the solenoid or combination of solenoids responsible for that gear ratio. This can be a tricky situation, as the same performance codes also can set when a clutch in charge of holding the gear ratio is slipping or neutraling out. Immediately throwing new solenoids at the problem can be an expensive mistake if the clutch actually is to blame. The key to diagnosing the problem right the first time is verifying solenoid commands and gear ratios with a thorough road test and capable scan tool.

The trouble area that these three transmissions have in common relates to the feed that these solenoids are provided. On-Off solenoids typically are fed reduced pressure from a solenoid modulator valve or fed line pressure through a very small orifice to prevent flooding. Oddly enough, these 6-speed solenoids are fed regulated, non-orificed line pressure from the manual valve. You can count this as your little-known and even less-cared-for fact of the day, but it’s an extremely important one.

The significance of the unusual feed system is where our problem lies, because there is another On-Off solenoid connected to same oil circuit feeding the solenoids: the SR solenoid. This particular solenoid does not have a performance code connected to it to aid in diagnosis. The fact of the matter is that the trouble codes listed above really are of no help other than pointing us to the solenoids. The actual problem is deeper…it is the solenoid喂养.

|

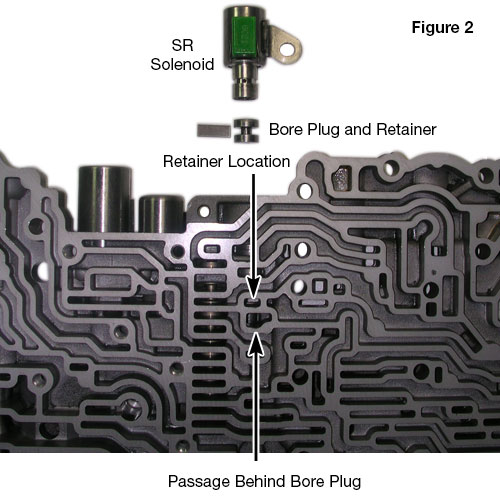

Figure 1示出了S1,S2,S3,S4和SR螺线管的位置,在那里您可以从SR螺线管从孔中看到孔中的排气口更深。该端口直接位于固定口袋下方,用于位于SR电磁阀后面的孔插头(Figure 2shows the OE bore plug and retainer removed from the valve body).

|

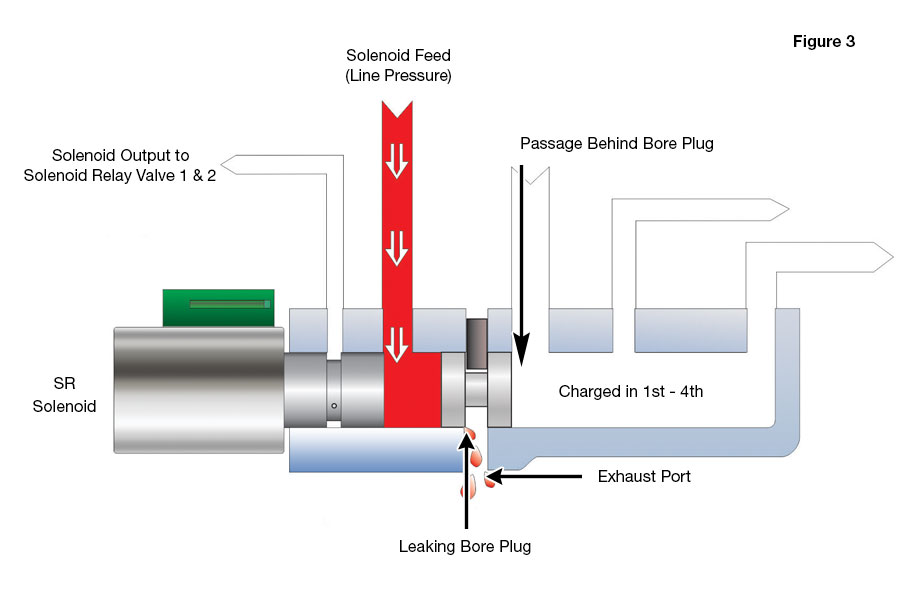

This bore plug separates solenoid feed (line pressure) and a circuit that is charged in first through fourth gears (Figure 3).

|

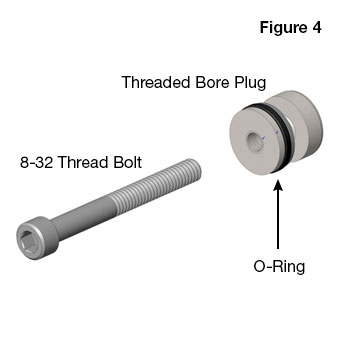

This problem area was discovered by Jeff Parlee, director of product support at Valve Body Xpress, and it was easy to see when run on the valve body test machine. As soon as the line pressure circuit was charged, oil started dumping out of the exhaust port. It was one of those “that can’t be right!” moments, and of course it is不是right. Not every shop out there has a valve body test machine, so this problem can be missed very easily. A good repair for this area is an O-ringed bore plug that is threaded so it can be installed down into the bore with ease (Figure 4). The O-ring prevents solenoid feed (which we know now is line pressure) from leaking into the sump. This leak not only causes low solenoid feed, but also low line pressure that we all know is not good.

|

|

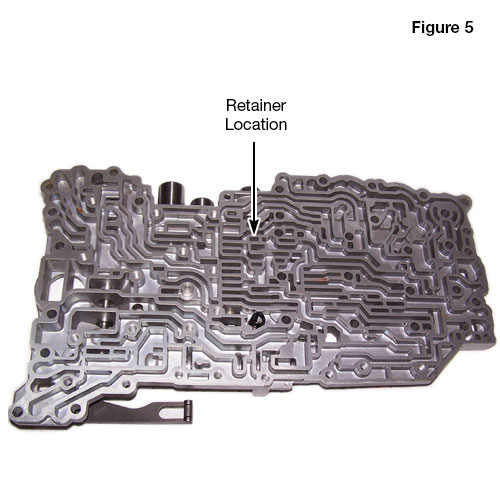

Removing the OE bore plug is where the challenge lies.Figure 5显示该钻孔插头保持器的位置。大型纸夹和针头钳可以帮助将该孔插头推出其位置,从排气口和/或其后面的通道(图2和3)开始。顺便说一下,这是清洁时总是从铸件中脱离的那样,因为没有阀门或弹簧,这里有这种阀门或弹簧以保持压力。

I hope this overview of solenoid diagnostics has been helpful and proves that little-known and even less-cared-for facts are important to diagnosing hard-to-find problems.

Related Units

Related Parts

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.