法兰的轭Showdown

Sonnax Flange Yokes vs. Spicer Flange Yokes

Racers and technicians are always on the lookout for stronger, lighter parts to install that will give a performance advantage or upgrade. Often, comparing competing parts can be difficult due to a lack of concrete testing evidence to consult, and limited availability of appropriate product information. This is especially true of seemingly “simple” hard parts such as flange yokes. Recent comparison testing of aSonnax (aluminum) 1859 flange yokeversus aSpicer (steel)1859 flange yokeprovides valuable insight into some key differences between the two.

| Sonnax 1859 |

Spicer 1859 |

|---|---|

|

|

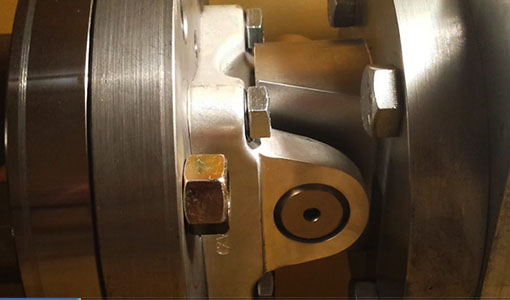

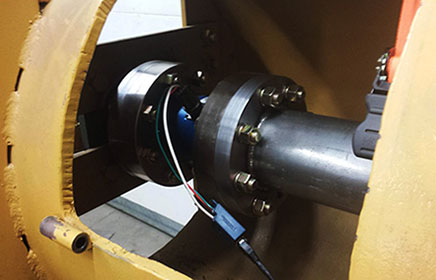

The yokes were tested at the Sonnax technical center in Vermont using a torsional test machine (Figure 1).精确的扭矩水平应用和测量with a torque load transducer (Figure 2). Applied torque was incrementally increasedin an attempt to find each yoke’s ultimate failing point.

| Figure 1 | Figure 2 |

|---|---|

|

|

Test results reveal that the Spicer flange yoke and the Sonnax flange yoke fail at identical maximum torque loads, which demonstrates that the strength-to-yield of these yokes is equal.However, though they have corresponding durability, the yokes display quite different modes ofterminal failure.

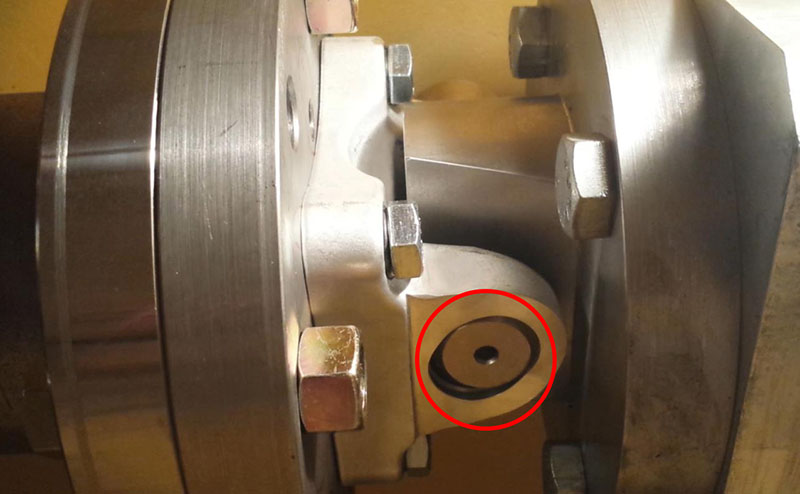

When the Sonnax yoke reached the failure torque load, its aluminum construction plastically yielded, stretching the U-joint bores into ovals but holding on to the driveshaft (Figure 3).

| Figure 3 |

|---|

|

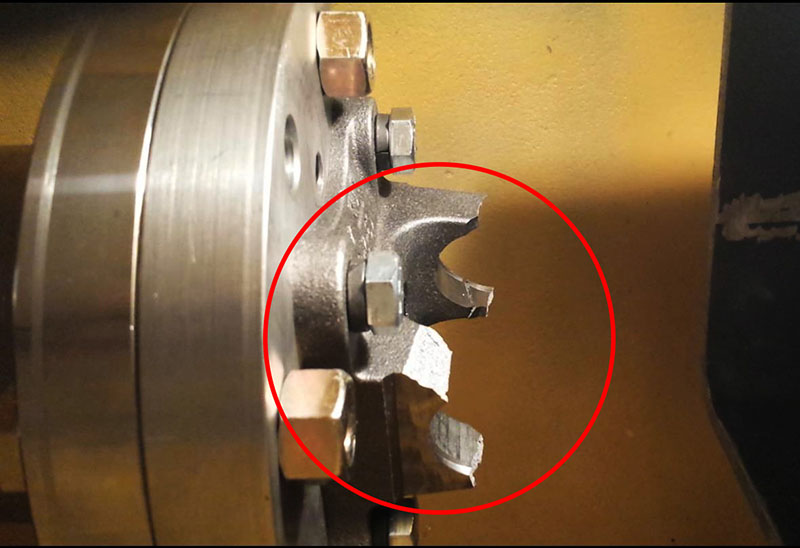

In contrast, when the Spicer yoke failed it did so catastrophically, shattering like glass and disconnecting from the driveshaft (Figure 4).

| Figure 4 |

|---|

|

A complete breach such as this can result in grievous damage to other vehicle components due to an unsecured driveshaft whip-sawing out of control at high speed. The exhaust system, fuel tank and lines, brake lines, transfer case and/or tail shaft can be mangled along with the driveshaft in such a situation. Track personnel and bystanders may also face a heightened risk of injury in this scenario due to broken pieces being launched outward.

In addition to this formidable advantage, the Sonnax flange yoke exhibits clear superiority in the following important areas:

- Reduced Rotating Mass— The Sonnax yoke is half the weight of the Spicer yoke. Reducing rotating mass yields exponential weight savings as compared to simply lowering static vehicle weight.

- Balance— The forging and machining processes employed by Sonnax result in a yoke that arrives balanced and ready to install right out of the box. This is not the case with the cast Spicer yoke.

- Time Savings— Since no balancing is required, valuable time and money can be preserved and spent on other areas of the build.

Related Parts

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.